Introduction

Potted miniature roses (Rosa hybrida L.) are beloved for their compact size, vibrant blooms, and versatility as ornamental plants. However, maintaining their postproduction quality poses challenges, including leaf yellowing, flower drop, and ethylene sensitivity. This guide explores their botanical background, production techniques, postharvest management, and future breeding innovations.

Botanical Classification

Rosa hybrida L., commonly referred to as roses, belongs to the following taxonomic hierarchy:

- Domain: Eukaryota

- Kingdom: Plantae

- Phylum: Magnoliophyta

- Class: Magnoliopsida

- Order: Rosales

- Family: Rosaceae

- Genus: Rosoideae

- Species: Rosa L. (Wild Rose)

Natural Distribution

Roses naturally thrive in the northern hemisphere, with wild species found as far north as Greenland and Siberia. Their habitats span:

- Mediterranean Region: Known for its biodiversity and temperate climate.

- East Asia: Particularly in Myanmar and China, which host diverse species.

- North America: Around the Gulf of Mexico, supporting wild forms.

Botanical Description

Most ornamental roses available today, including popular potted miniature varieties, are hybrids—carefully bred to enhance their aesthetic appeal and commercial viability. Over centuries, selective breeding has produced roses with diverse colors, forms, and growth habits, making them a staple in horticulture.

The flower structure of roses follows a classic botanical design: each bloom consists of five sepals (protective outer leaves) and five petals, arranged in a symmetrical, often layered fashion. At the center, numerous stamens (male reproductive organs) surround a prominent ovary (female reproductive structure), which later develops into the rose hip if pollination occurs.

Interestingly, despite not producing nectar, roses efficiently attract pollinators such as bees and butterflies through their strong, sweet fragrance. This scent, combined with their bright colors, ensures successful insect-mediated pollination. Some modern cultivars have been bred for enhanced fragrance, while others prioritize visual traits, reflecting the diverse goals of rose hybridization.

The compact growth habit of miniature roses makes them ideal for containers, but their botanical fundamentals remain the same as their larger counterparts. Understanding these traits helps growers optimize cultivation techniques, from propagation to postharvest care, ensuring healthy plants with vibrant, long-lasting blooms.

Production & Cultivation

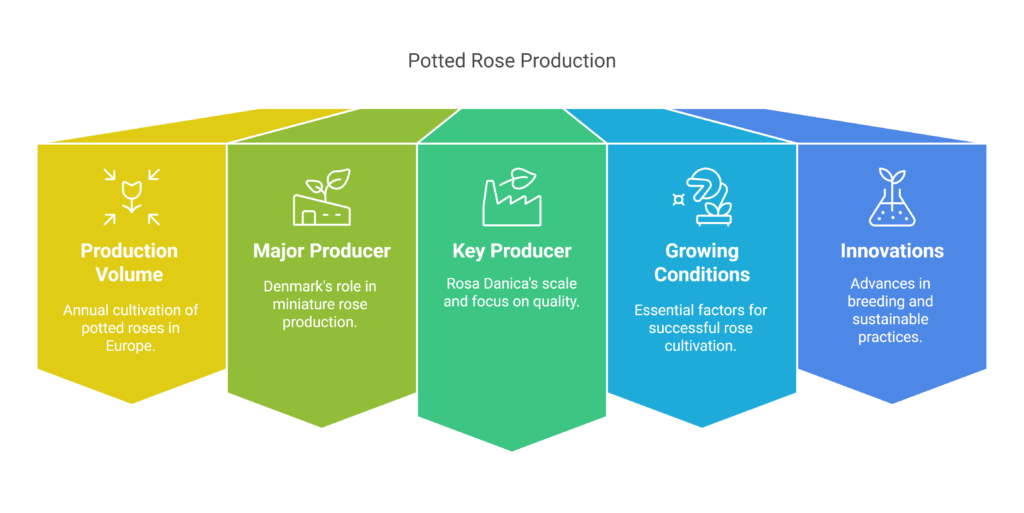

The global production of potted roses is a thriving sector within the ornamental horticulture industry, with Europe leading as a key producer. Approximately 60 million potted roses are cultivated annually across the continent, supplying both local markets and international exports. Among European countries, Denmark stands out as a major hub for high-quality miniature rose production, thanks to its advanced greenhouse technologies and efficient cultivation practices.

The success of potted rose cultivation in Denmark and other leading regions relies on optimized growing conditions, including controlled climate greenhouses, precise irrigation systems, and integrated pest management. Additionally, innovations in breeding, propagation, and postharvest treatments ensure that these miniature roses meet consumer demands for longevity, visual appeal, and disease resistance. As the market for ornamental plants continues to grow, advancements in sustainable production methods—such as reduced chemical use and energy-efficient lighting—are shaping the future of potted rose cultivation.

Breeding Goals

Modern rose breeding programs focus on developing cultivars that excel in both aesthetic qualities and commercial viability. Breeders prioritize four key characteristics to meet market demands and production challenges:

a). Optimized Plant Architecture

Contemporary breeding aims to create roses with naturally compact growth habits and short internodes, reducing reliance on chemical growth regulators. Ideal cultivars exhibit dense branching patterns and sturdy stems capable of supporting abundant blooms without staking. This architectural optimization allows for efficient greenhouse space utilization and creates market-ready plants that maintain their form throughout the post-production chain. The industry is particularly interested in genotypes requiring minimal or no paclobutrazol applications, addressing both environmental concerns and production cost reduction.

b). Enhanced Disease Resistance

Breeders employ both traditional selection and molecular techniques to develop roses with improved resistance to major pathogens like powdery mildew (Podosphaera pannosa), black spot (Diplocarpon rosae), and botrytis (Botrytis cinerea). Resistance breeding focuses on multiple defense mechanisms, including thicker cuticles, antimicrobial compounds, and systemic acquired resistance. This reduces fungicide dependency while improving plant health during production and post-retail phases, directly impacting consumer satisfaction.

c). Extended Postharvest Performance

A primary breeding target involves improving ethylene tolerance and natural longevity. Superior cultivars demonstrate delayed senescence responses, maintaining turgor and color integrity during transport and home display. Breeders evaluate potential cultivars under simulated retail conditions, selecting for traits like reduced leaf abscission, slower petal wilting, and resistance to “bent neck” phenomenon. Recent advances include incorporating the etr1-1 ethylene receptor mutation through both conventional and biotechnological approaches.

d). Enhanced Floral Characteristics

The visual appeal remains paramount in cultivar selection. Breeding programs seek:

- Novel color patterns and stable pigmentation

- Symmetrical, high petal-count blooms

- Gradual, uniform flowering progression

- Pleasant, persistent fragrances

- Abundant bud production for continuous flowering

Propagation Techniques of Potted Miniature Roses

a). Vegetative Propagation via Stem Cuttings

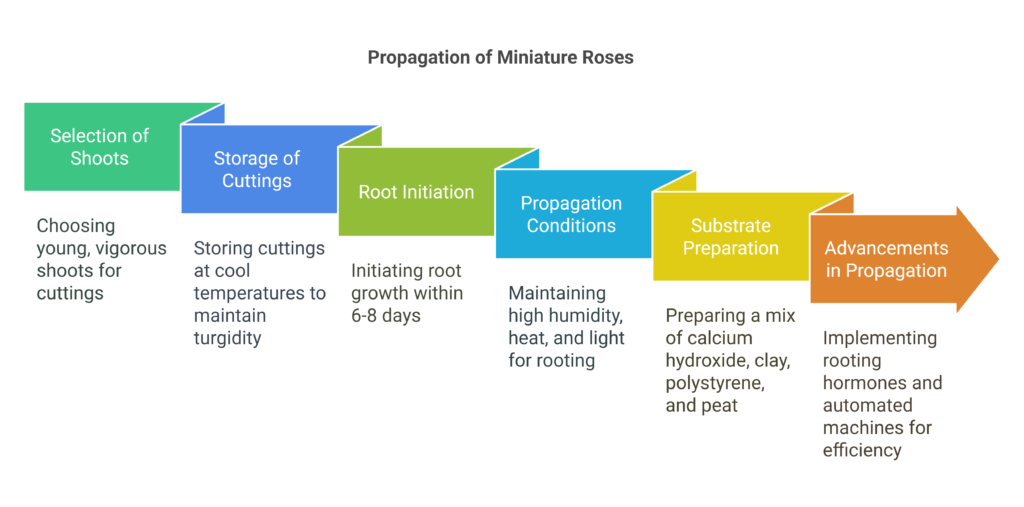

The commercial production of potted miniature roses predominantly relies on vegetative propagation through stem cuttings, a method that ensures genetic uniformity and maintains cultivar characteristics. Producers typically select young, vigorous shoots that are 16-20 days old from the mother plants, with cuttings taken from the second flush of growth to ensure optimal rooting potential. These cuttings are immediately stored at cool temperatures between 2-5°C to maintain turgidity and slow metabolic activity until planting.

Under ideal propagation conditions, root initiation begins within 6-8 days after sticking. The rooting process is carefully managed in specialized propagation environments with:

- High relative humidity (90-100%)

- Bottom heat maintaining substrate temperature at 22-24°C

- Diffused light intensity of 60-70 W/m²

- Regular misting to prevent desiccation

The rooting substrate plays a critical role in successful propagation. A carefully formulated mix typically contains:

- Calcium hydroxide [Ca(OH)₂]: Adjusts pH and provides calcium for cell wall development

- Clay components: Improves water retention and cation exchange capacity

- Polystyrene beads: Enhances aeration and drainage in the root zone

- Peat or coco coir: Provides organic matter and moisture regulation

This optimized propagation system allows commercial growers to produce uniform, high-quality rooted cuttings ready for transplanting in 3-4 weeks. The process is carefully timed to synchronize with production schedules, ensuring year-round availability of starter plants for greenhouse cultivation. Recent advancements include the use of rooting hormones in gel formulations and automated sticking machines that improve both efficiency and success rates in large-scale operations.

b). Propagation Climate

The propagation environment for miniature roses requires precise climate control to ensure successful rooting and early growth development. Maintaining optimal conditions significantly impacts rooting percentages, propagation speed, and cutting quality.

i). Temperature Management

The propagation area implements a carefully controlled dual-temperature system where air temperatures are maintained at 20-24°C while the rooting media is kept slightly warmer at 22-24°C through bottom heating systems, creating a strategic thermal gradient that optimizes cutting performance by accelerating root initiation through enhanced cell division in the warmer root zone while simultaneously reducing moisture stress in the foliage through moderately cooler air temperatures, with the 2-4°C differential specifically designed to stimulate rapid root development without causing excessive transpiration that could dehydrate the vulnerable cuttings during this critical establishment phase.

ii). Humidity Control

The propagation process employs a carefully staged humidity protocol that begins with near-saturation conditions (~100% RH) maintained during the critical first 5 days through fogging systems or enclosed environments, then systematically reduces to 95% RH over days 5-10 as cuttings begin root formation, before finally stabilizing at 85% RH after day 10 to complete the hardening process, thereby creating a controlled transition that gradually shifts the cuttings’ reliance from ambient humidity to self-sustaining root-based water absorption while significantly reducing stress that could compromise establishment success.

iii). Light Requirements

The propagation area delivers optimized lighting conditions with an intensity of 60-70 W/m² (200-250 μmol/m²/s PPFD) through full-spectrum LEDs or fluorescent lamps specifically enhanced in the blue spectrum, coupled with continuous 24-hour illumination to sustain consistent photosynthetic activity in developing cuttings while effectively suppressing excessive stem elongation, thereby producing stocky, vigorously rooted propagules with ideal morphology for successful transplantation and further growth.

This carefully calibrated light regime ensures cuttings maintain adequate carbohydrate production through photosynthesis while the spectral quality and uninterrupted photoperiod work synergistically to promote compact growth habits and robust root development, critical factors for producing high-quality, transplant-ready plant material. The blue-light enriched spectrum particularly enhances stomatal regulation and chloroplast development, contributing to the cuttings’ overall vitality during this vulnerable propagation stage.

c). Alternative Propagation Methods

i). Generative (Seed) Propagation

While vegetative propagation remains the primary method for commercial rose production due to its efficiency and uniformity, generative (seed) propagation plays several specialized but crucial roles in horticulture, particularly in breeding programs where developing new cultivars demands genetic recombination and variability, in producing vigorous rootstocks for grafted roses that combine desirable traits from different plants, and in conservation initiatives aimed at preserving wild rose species and their genetic diversity; however, this sexual propagation method comes with the significant drawback of extended production timelines, typically requiring 12-18 months to reach flowering maturity compared to the mere 8-10 weeks needed for cuttings to develop into marketable plants, making it commercially impractical for standard production despite its importance for genetic innovation and preservation.

ii). Micropropagation in Rose Cultivation

Tissue culture techniques offer unique advantages for specialized applications in rose production. These methods enable the rapid multiplication of new cultivars, allowing breeders to quickly scale up promising varieties. Additionally, micropropagation plays a critical role in generating pathogen-free stock plants, ensuring healthier and more uniform crops. The technique is also indispensable for genetic modification research and the conservation of rare or endangered rose genotypes, preserving valuable genetic material for future breeding efforts.

Current micropropagation protocols primarily rely on somatic embryogenesis, using petiole or leaf explants to regenerate complete plants. Despite its potential, widespread commercial adoption has been hindered by several challenges. High production costs, technical complexity, and stringent regulatory restrictions—particularly concerning genetically modified ornamentals—have limited its use primarily to research and elite cultivar development.

However, emerging technologies such as bioreactor systems and automation are beginning to address these barriers. These innovations promise to reduce costs, improve efficiency, and enhance scalability, potentially making micropropagation a more viable option for high-value rose production in the future. As these advancements progress, tissue culture could become an increasingly important tool for rose growers seeking precision, speed, and genetic consistency in their cultivation practices.

Production Climate & Management

Commercial production of potted miniature roses requires precise environmental management to ensure optimal growth and flowering:

a). Temperature Regulation

Maintained at 19-20°C throughout the production cycle, this temperature range promotes steady vegetative growth while encouraging flower development. The relatively cool temperatures help maintain compact plant habit and prolong flowering duration.

b). Light Management

- Intensity: 60-100 W/m² (approximately 250-400 μmol/m²/s PPFD)

- Duration: 20-22 hours of daily light exposure

- Supplemental lighting using high-pressure sodium (HPS) or LED fixtures ensures consistent growth during low-light seasons, particularly important for day-neutral rose varieties.

c). CO₂ Enrichment

Maintained at 1000 ppm for 16-18 hours daily during daylight periods, significantly enhancing photosynthesis rates and flower production. This elevated CO₂ level is typically achieved through controlled injection systems in modern greenhouses.

d). Humidity Control

Kept within 60-80% relative humidity to balance transpiration rates and minimize disease pressure. Automated systems with humidity sensors and vent controls maintain this range, preventing both moisture stress and fungal development.

Essential Cultural Practices

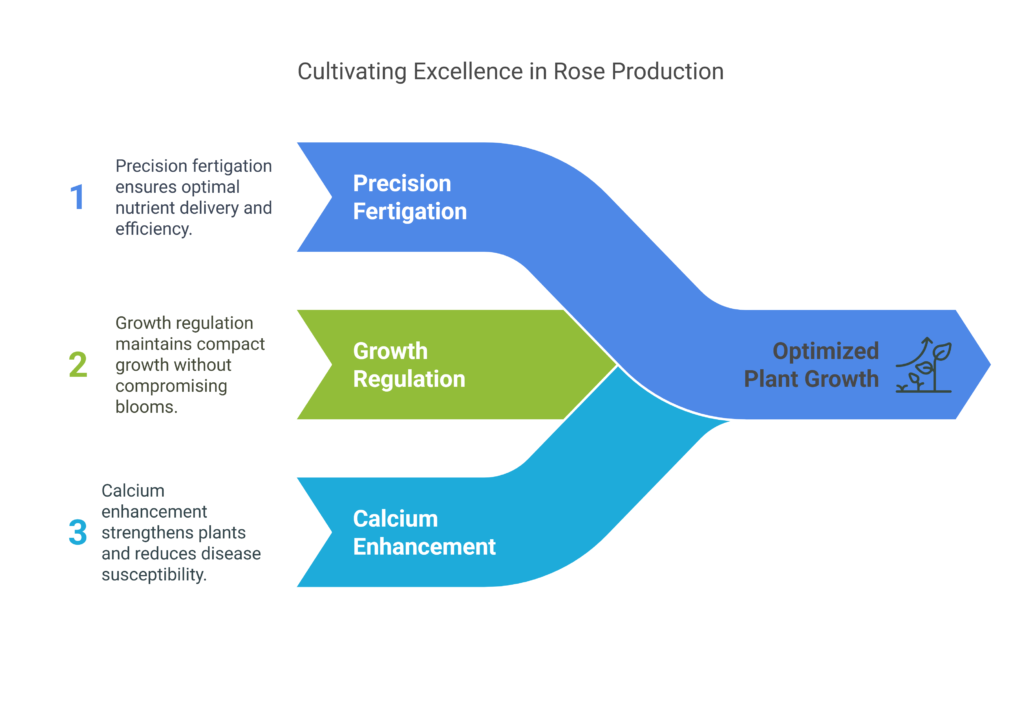

a). Precision Fertigation

Modern precision fertigation systems optimize plant nutrition by maintaining key parameters including a 1.5 mS/cm² electrical conductivity (EC) to ensure ideal nutrient concentration and a carefully adjusted pH of 5.5 for maximum nutrient availability, while delivering a precisely balanced NPK (Nitrogen, Phosphorus, Potassium) solution enriched with essential micronutrients through advanced drip irrigation technology that targets root zones directly, thereby minimizing resource waste, enhancing water use efficiency, and promoting superior plant growth and development through this highly controlled and efficient nutrient delivery method.

b). Growth Regulation

In modern rose production, growth regulation is achieved through strategic applications of paclobutrazol (marketed as Bonzi) at a 0.5% concentration, with 2-7 treatments administered throughout the production cycle at precisely timed intervals determined by specific cultivar characteristics and developmental stages, effectively controlling plant stature while preserving floral excellence by maintaining desirable compact growth habits without negatively impacting bloom size, quantity, or visual appeal.

c). Calcium Enhancement Program

The calcium enhancement program implements a dual-approach strategy, combining liquid applications of 200 ppm calcium in irrigation water with substrate amendments of 4.5 kg/m³ calcium-containing additives, which collectively strengthen cellular walls to reduce Botrytis susceptibility, extend post-production shelf life, and boost overall plant vitality, while carefully maintaining substrate pH between 6.0-6.5 to ensure optimal calcium uptake and prevent nutrient lock-up that could compromise plant health and development.

Postharvest Challenges and Innovative Solutions for Miniature Roses

a). Primary Senescence Challenges

Potted miniature roses face several critical postproduction issues that impact on their marketability and consumer satisfaction:

i). Premature Abscission Problems

Postharvest deterioration in miniature roses manifests primarily through leaf, flower, and bud drop, physiological responses triggered by ethylene sensitivity and water stress that become particularly acute during the vulnerable transport and retail display phases, with certain high-sensitivity cultivars experiencing catastrophic losses of 50-70% of their buds within just five days when exposed to suboptimal handling conditions, temperature fluctuations, or inadequate humidity control.

This complex postproduction challenge stems from the activation of abscission zones at the base of pedicels and petioles when plants encounter ethylene concentrations as low as 0.1-0.5 ppm combined with moisture stress, creating a cascade of enzymatic activity that weakens cell walls and disrupts auxin transport, ultimately leading to organ detachment that significantly reduces marketability and consumer appeal, particularly in popular but sensitive varieties like ‘Orange Meillandina’ and ‘Sunblaze’ which show accelerated deterioration patterns compared to more durable cultivars such as ‘Scarlet’ or ‘American Independence’.

ii). Yellowing Disorders

The postharvest physiology of miniature roses is significantly impacted by yellowing disorders, most notably manifested through the characteristic “bent neck” phenomenon where stems structurally collapse just below the flower head due to weakened vascular tissues, accompanied by progressive chlorosis that initially appears in mature leaves before spreading to younger foliage, with these degenerative processes being markedly accelerated by periods of light deprivation during shipping and storage which disrupt normal photosynthetic activity and carbohydrate mobilization, ultimately leading to rapid chlorophyll degradation and loss of structural integrity in the stems.

These physiological disorders stem from complex interactions between ethylene sensitivity, carbohydrate depletion, and water stress, where the absence of light during transport not only reduces available energy reserves but also disrupts normal hormone balance, exacerbating the breakdown of chlorophyll pigments and cell wall components that collectively contribute to both the visual yellowing symptoms and the mechanical failure of stems, with certain cultivars demonstrating particular susceptibility based on their genetic predisposition to postharvest disorders and varying capacities for carbohydrate storage and ethylene resistance.

iii). Pathogen Infections

Postharvest pathogen infections pose a serious threat to miniature rose quality, with Botrytis cinerea (gray mold) emerging as the most destructive fungal pathogen that primarily targets senescing flowers and wounded tissues during the postproduction phase, thriving in the high-humidity conditions often encountered during storage and transport, where its rapid proliferation can lead to devastating complete crop losses if left uncontrolled.

This necrotrophic fungus exploits even minor injuries or natural senescence processes to establish infection, producing characteristic grayish spores that quickly spread to adjacent healthy tissue, with the problem being particularly acute in ethylene-sensitive cultivars where accelerated aging creates more infection sites.

The economic impact is magnified by the pathogen’s ability to remain latent during cooling and then resume aggressive growth when temperatures rise during retail display, making integrated management combining cultural practices, environmental control, and targeted fungicide applications critical for preserving product viability throughout the postharvest chain.

b). Ethylene: The Invisible Threat

As highly ethylene-sensitive ornamentals, miniature roses face multiple exposure risks:

i). Common Ethylene Sources

Miniature roses face significant ethylene exposure from multiple sources throughout the postharvest chain, beginning with transportation where diesel exhaust in truck cabins can contain up to 5 ppm of this damaging plant hormone, followed by retail environments where proximity to produce sections exposes flowers to ethylene emissions from fruits like apples (releasing 10-100 ppb), and finally reaching consumers where cigarette smoke presents an extreme ethylene concentration of 200-500 ppm, with each of these exposure points capable of triggering premature senescence even at remarkably low concentrations (as little as 0.1 ppm), necessitating comprehensive protection strategies throughout the entire distribution network to maintain floral quality.

ii). Physiological Impact

The physiological impact of ethylene on miniature roses is profound and multifaceted, triggering a cascade of detrimental effects including the activation of abscission zone formation in petioles that leads to premature leaf and flower drop, while simultaneously accelerating membrane degradation in petals through lipid peroxidation and cellular breakdown, with the hormone additionally stimulating a dramatic increase in respiration rate that rapidly depletes carbohydrate reserves and starves the plant of essential energy needed to maintain turgor pressure and floral longevity, ultimately resulting in visible wilting, color fading, and structural collapse that significantly diminishes both vase life and marketability.

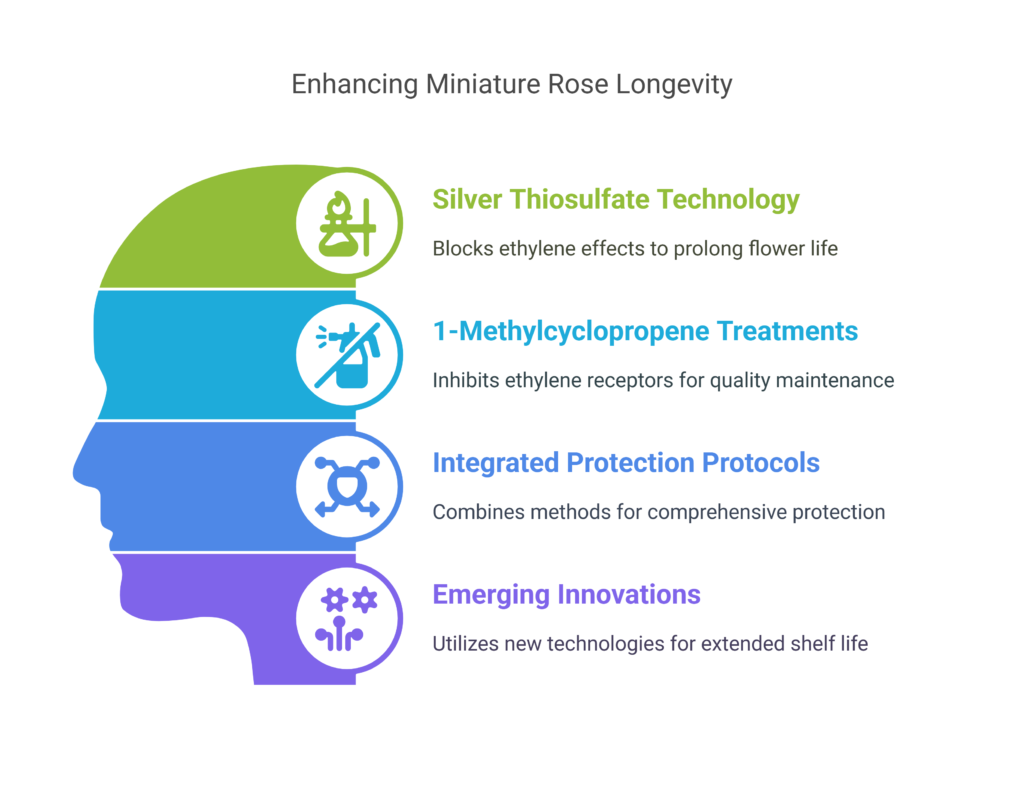

Advanced Postharvest Solutions

a). Silver Thiosulfate (STS) Technology

The physiological impact of ethylene on miniature roses is profound and multifaceted, triggering a cascade of detrimental effects including the activation of abscission zone formation in petioles that leads to premature leaf and flower drop, while simultaneously accelerating membrane degradation in petals through lipid peroxidation and cellular breakdown, with the hormone additionally stimulating a dramatic increase in respiration rate that rapidly depletes carbohydrate reserves and starves the plant of essential energy needed to maintain turgor pressure and floral longevity, ultimately resulting in visible wilting, color fading, and structural collapse that significantly diminishes both vase life and marketability.

b). 1-Methylcyclopropene (1-MCP) Treatments

The ethylene action inhibitor 1-Methylcyclopropene (1-MCP), commercially available as EthylBloc®, is applied at concentrations of 0.5-1.0 g/m³ to effectively block ethylene receptors in miniature roses for 7-14 days, with multiple application methods including pre-shipping fumigation (24-hour exposure in sealed chambers), incorporation of slow-release sachets in consumer packaging, and direct treatment of retail display areas, providing comprehensive protection throughout the postharvest chain by preventing ethylene binding and subsequent senescence signaling while maintaining flower quality during transport, storage, and final sale.

c). Integrated Protection Protocols

To maximize postharvest quality and longevity in miniature roses, integrated protection protocols combine multiple synergistic approaches: immediate pre-cooling to 10-12°C after harvest rapidly reduces metabolic activity, while modified atmosphere packaging with 3-5% O₂ and 5-10% CO₂ creates an optimized gaseous environment that slows respiration; these measures are complemented by fungicide dips using thiophanate-methyl and fludioxonil to control Botrytis cinerea, along with careful humidity maintenance at 85-90% to prevent desiccation without promoting fungal growth, forming a comprehensive defense system that addresses physiological, pathological, and environmental challenges throughout the postproduction chain.

This multi-barrier strategy effectively extends vase life by simultaneously inhibiting ethylene effects, reducing microbial spoilage, and maintaining tissue turgor, while the specific combination of technologies can be adjusted based on cultivar sensitivity, transport duration, and market requirements to ensure optimal results under varying commercial conditions.

d). Emerging Innovations

The postharvest handling of miniature roses is being revolutionized by cutting-edge innovations, including CRISPR-engineered cultivars with ethylene-insensitive traits, nano-silver antimicrobial packaging coatings, biodegradable films that gradually release 1-MCP, and specialized LED lighting systems that maintain photosynthetic activity during transport. These technological advancements work synergistically to dramatically extend shelf life from the conventional 5-7 days to an impressive 14-21 days under ideal conditions, effectively minimizing product losses throughout the supply chain while enhancing floral quality and longevity.

The integration of genetic engineering, nanotechnology, controlled-release chemistry, and photobiology represents a transformative approach to postharvest management that addresses both physiological and pathological challenges simultaneously, offering the potential to significantly improve economic returns for growers, distributors, and retailers while delivering superior products to consumers.

Efficacy of Cytokinin Treatments in Preventing Leaf Yellowing

a). Experimental Findings on ‘Meijikatar’ Miniature Roses

Recent research on ‘Meijikatar’ miniature roses reveals cytokinins’ exceptional efficacy in preserving foliage quality during postharvest transport, with controlled experiments showing untreated controls developing severe leaf yellowing (increasing from 12.5% at day 3 to 43.1% at day 5 under 16°C simulated transport conditions), while cytokinin treatments demonstrated dramatic protective effects – benzyladenine (BA) at 100 µM concentration proved most potent (limiting yellowing to merely 0.8% and 5.1% at days 3 and 5 respectively), followed by the cytokinin-gibberellin blend Promalin (100 µM maintaining 2.0% and 7.1% yellowing), and trans-zeatin (TZ) (100 µM showing 2.5% and 18.5% yellowing), collectively establishing cytokinins as crucial tools for mitigating postharvest chlorophyll degradation in miniature rose cultivars.

b). Cultivar-Specific Postharvest Performance

Genetic predisposition significantly impacts miniature rose longevity, with dramatic differences observed among popular cultivars:

i). High-Senescence Cultivars

- ‘Orange Meillandina’: Particularly prone to rapid flower abscission and leaf chlorosis

- ‘Sunblaze’: Shows accelerated petal wilting and pedicel abscission

ii). Superior-Performing Cultivars

- ‘Scarlet’: Maintains turgor pressure and pigment stability

- ‘American Independence’: Demonstrates exceptional ethylene tolerance

The Future of Rose Cultivation: Biotechnology and Breeding Innovations

a). Genetic Breakthroughs in Rose Development

i). Ethylene-Insensitive Varieties

The development of ethylene-insensitive rose varieties through integration of the etr1-1 gene from Arabidopsis thaliana marks a breakthrough in postharvest management, as this dominant-negative mutation produces dysfunctional ethylene receptors that prevent normal senescence responses, with field trials demonstrating transgenic lines maintain freshness 3-5 times longer than conventional cultivars, potentially eliminating the need for chemical ethylene inhibitors in commercial production while significantly extending vase life.

ii). Compact Growth Modification:

The introduction of the Shi (Short internodes) gene offers a groundbreaking solution for achieving compact growth in roses, naturally reducing internode length by 30-50% without compromising flowering capacity or requiring traditional plant growth regulators, making it especially beneficial for organic cultivation systems while potentially lowering production costs by eliminating the need for chemical growth retardant applications.

iii). Enhanced Disease Resistance:

MKS1 substrate technology represents an innovative plant protection strategy that activates systemic acquired resistance, offering broad-spectrum defense against both fungal and bacterial pathogens while working synergistically with the plant’s natural immune system, with field trials confirming its remarkable efficacy through demonstrated 60-80% reductions in Botrytis incidence, providing growers with an effective tool for disease management without relying solely on traditional fungicides.

b). The GMO Acceptance Challenge

Despite these technological advances, significant barriers remain:

i). Regulatory Hurdles

Commercializing transgenic ornamentals faces major hurdles, including inconsistent global regulations, lengthy 5-7 year approval processes per cultivar, and high costs ($2-5 million per trait), creating significant market barriers despite their potential benefits. These challenges stem from complex biosafety requirements and extensive field testing, slowing innovation and delaying improved varieties from reaching consumers.

ii). Consumer Perception Issues

The commercialization of GM roses faces significant consumer perception challenges, including lingering “Frankenflower” stigma despite scientific evidence of safety, a strong preference among environmentally-conscious buyers for traditionally-bred varieties, and consequent retailer hesitancy to carry genetically modified floral products, creating substantial market barriers even for cultivars with clear consumer benefits. These perception issues stem from deeper concerns about genetic manipulation, lack of understanding about biotechnology processes, and general skepticism toward engineered ornamentals, despite their potential advantages like extended vase life or reduced pesticide requirements, forcing breeders to carefully consider public acceptance when developing new GM rose varieties for the horticulture market.

iii). Market Realities

The commercialization of GM roses faces economic hurdles as current price premiums fail to cover development costs, while complex labeling mandates and divergent international regulations create additional trade barriers between GM-friendly and resistant markets.

iv). Emerging Solutions

Emerging solutions for GM rose acceptance include CRISPR editing as a consumer-friendly alternative, targeted education on sustainability benefits, marker-free transformation systems, and focusing on desirable traits like enhanced fragrance to increase market appeal.

Conclusion

Potted miniature roses require precise cultivation and postharvest care to maintain quality. Advances in cytokinin treatments, ethylene inhibitors, and genetic engineering promise longer-lasting, resilient varieties. As breeding evolves, future roses may combine beauty, durability, and sustainability—meeting both grower and consumer demands.

References

Andersen, L., M.H. Williams, M. Serek, 2004. Reduced water availability improves drought tolerance of potted miniature roses; Is the ethylene pathway involved? Journal of Horticultural Science and Biotechnology 79: 1-13

Buanong, M., H. Mibus, E.C. Sisler and M. Serek, 2005. Efficacy of new inhibitors of ethylene perception in improvement of display quality of miniature potted roses (Rosa hybrida L.). Plant Growth Regulation 47: 29-38

Müller, R., E.C. Sisler and M. Serek, 2000. Stress induced ethylene production, ethylene binding, and the response to the ethylene action inhibitor 1-MCP in miniature roses. Scientia Horticulturae 83: 51-59.

Müller, R., S. Lind-Iversen, B.M. Stummann and M. Serek, 2000. Expression of genes for ethylene biosynthetic enzymes and an ethylene receptor in senescing flowers of miniature potted roses. Journal of Horticultural Science and Biotechnology 75: 12-18.

Zakizadeh, H., T. Debener, S. Sriskandarajah, S. Frello and M. Serek, 2008. Regeneration of miniature potted rose (Rosa hybrida L.) via somatic embryogenesis. European Journal of Horticultural Science 73: 111-117

Zakizadeh, H., H. Lütken, S. Sriskandarajah, M. Serek and R. Müller, 2013. Transformation of miniature potted rose (Rosa hybrida cv. Linda) with PSAG12-ipt gene delays leaf senescence and enhances resistance to exogenous ethylene. Plant Cell Reports 32: 195-205